Category: Power Wheelchair

Posted by 2025-12-26 11:12

hoyer lift fall

In-depth Analysis of Fall Risk Factors

Equipment-related Risks

Sudden lowering caused by hydraulic system failure

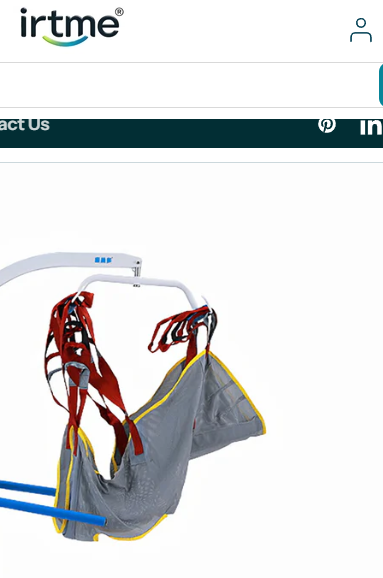

Support failure due to worn or torn slings

Accidental disengagement from faulty hook latches

Equipment movement resulting from ineffective base wheel brakes

Operation-related Risks

Caregivers’ insufficient training and non-standard operations

Inadequate communication before transfer

Hasty operations with neglected safety checks

hoyer lift fall

hoyer lift fall

Overloading the equipment

Environment-related Risks

Slippery or uneven floors

Narrow spaces restricting equipment operation

Insufficient lighting impairing visibility

Obstacles blocking the transfer path

Three-level Prevention System

Primary Prevention: Fundamental Prevention

Equipment Procurement Standards

Select hook systems with double safety locks

Ensure hydraulic systems have anti-sudden-drop devices

Choose models with stable bases

Operation Standardization

Develop written operation procedures

Establish an equipment inspection recording system

Implement a two-person verification mechanism

Secondary Prevention: Process Control

Pre-operation Inspection Checklist

Check sling integrity

Test hook latches

Test hydraulic systems

Evaluate floor conditions

Assess the user’s physical state

Real-time Monitoring Indicators

Changes in the user’s facial expressions

Abnormal equipment noises

Sling position deviation

Base stability status

Tertiary Prevention: Damage Control

Emergency Response Plans

First-response procedures after a fall

Medical assistance procedures

Incident reporting mechanisms

Rehabilitation Support

Psychological counseling services

Physical rehabilitation programs

Care resumption plans

Standardized Safety Inspection Procedures

Pre-use Inspection (Daily)

Visually inspect slings for wear

Manually test all hook latches

Test lifting/lowering functions with no load

Check wheel rotation and brakes

In-depth Inspection (Weekly)

Check for hydraulic oil leaks

Test emergency lowering devices

Inspect structural component stability

Clean and maintain moving parts

Professional Inspection (Monthly)

Load-bearing tests

System pressure detection

Validation of safety device effectiveness

Comprehensive maintenance

Emergency Response When a Fall Occurs

Phase 1: Immediate Response (0–2 minutes)

Stay calm and assess on-site safety

Call for help and activate emergency response

Protect the fallen person to prevent secondary injuries

Check consciousness and breathing

Phase 2: Initial Handling (2–10 minutes)

Conduct basic vital sign checks

Record details of the fall

Comfort the fallen person

Prepare for medical transportation

Phase 3: Follow-up (After 10 minutes)

Accompany the person to the hospital and provide detailed information

Conduct a root cause analysis of the incident

Develop plans to prevent recurrence

Provide psychological support

Fall Prevention Key Points for Special Populations

Patients with Cognitive Impairment

Use simple and clear operation prompts

Increase comfort measures during transfer

Avoid sudden movement changes

Physically Weak Patients

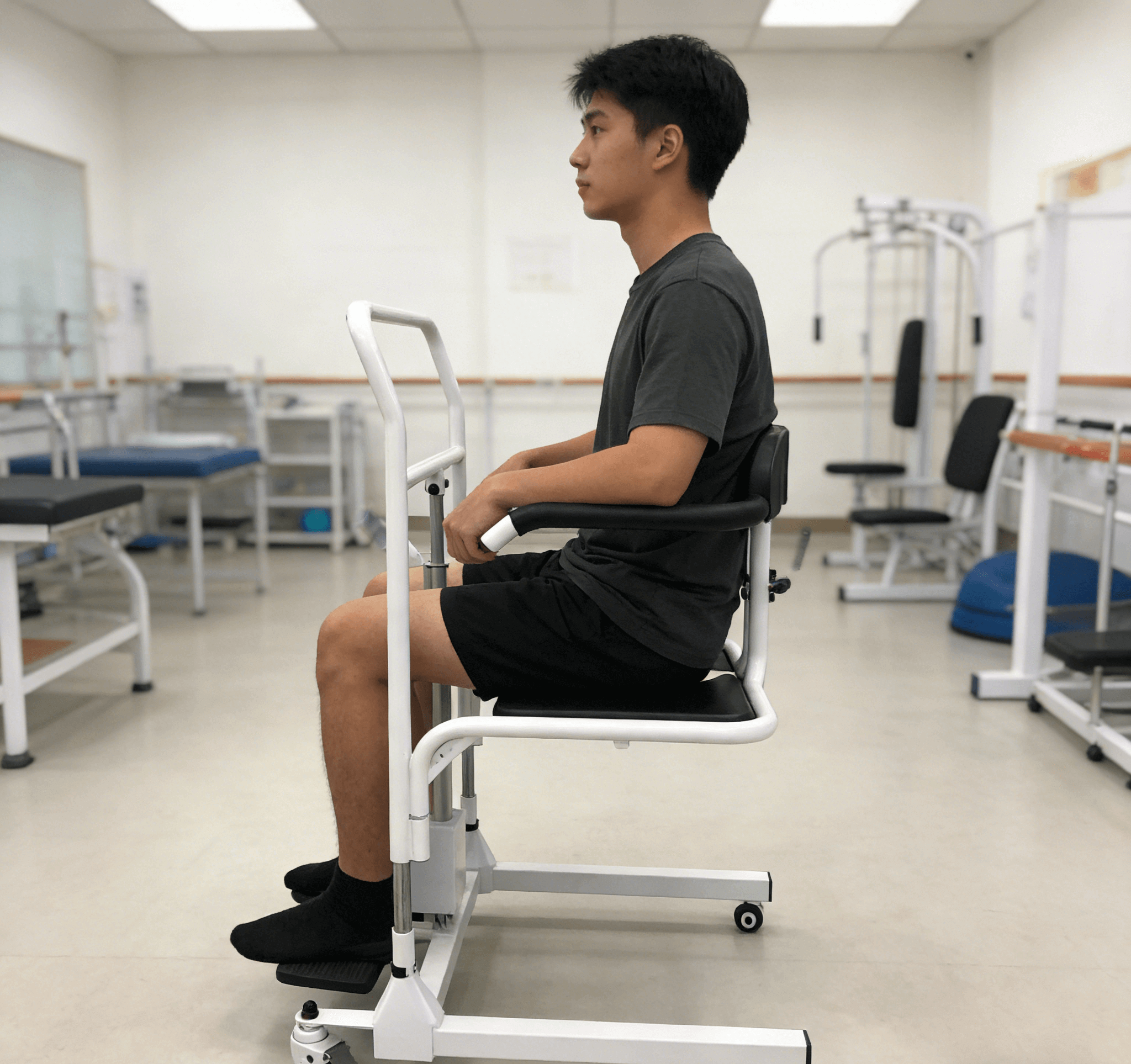

Adopt phased transfer methods

Provide additional support and protection

Extend transfer preparation time

Obese Patients

Use dedicated heavy-duty equipment

Ensure sufficient operation space

Consider two-person assisted operation

Training and Capacity Building

Basic Training Content

Understanding of equipment principles and structure

Training on standardized operation procedures

Development of safety inspection skills

Emergency response drills

Advanced Training Programs

Skills for handling complex situations

Ability to develop personalized plans

Team collaboration training

Learning quality control methods

Continuing Education Mechanisms

Quarterly retraining system

Case sharing sessions

Learning of new technologies

Experience exchange platforms

Technological Improvements and Innovations

Safety Device Upgrades

Intelligent weight sensing systems

Anti-fall mechanical protection devices

Automatic balance adjustment functions

Real-time monitoring and alarm systems

Auxiliary Equipment Innovations

Anti-slip transfer mats

Intelligent safety slings

Automatic positioning bases

Remote monitoring devices

Quality Improvement Cycle

Data Collection

Record key data for each transfer

Establish a near-miss reporting system

Collect user feedback

Track equipment maintenance records

Analysis and Improvement

Conduct regular data analysis

Identify risk trends

Develop improvement measures

Evaluate the effectiveness of measures

Standardization and Promotion

Standardize effective practices

Promote best practice sharing

Update training materials

Improve management systems

Conclusion

Preventing Hoyer Lift-related falls is an ongoing process that requires comprehensive and systematic solutions. hoyer lift fall By improving equipment maintenance, standardizing operation procedures, enhancing staff training, and establishing emergency systems, we can minimize fall risks. Remember, every safety detail is related to the dignity of life, and every standardized operation reflects professional care. Let us use professionalism and dedication to build a solid safety defense line, making care a truly warm and reliable presence.